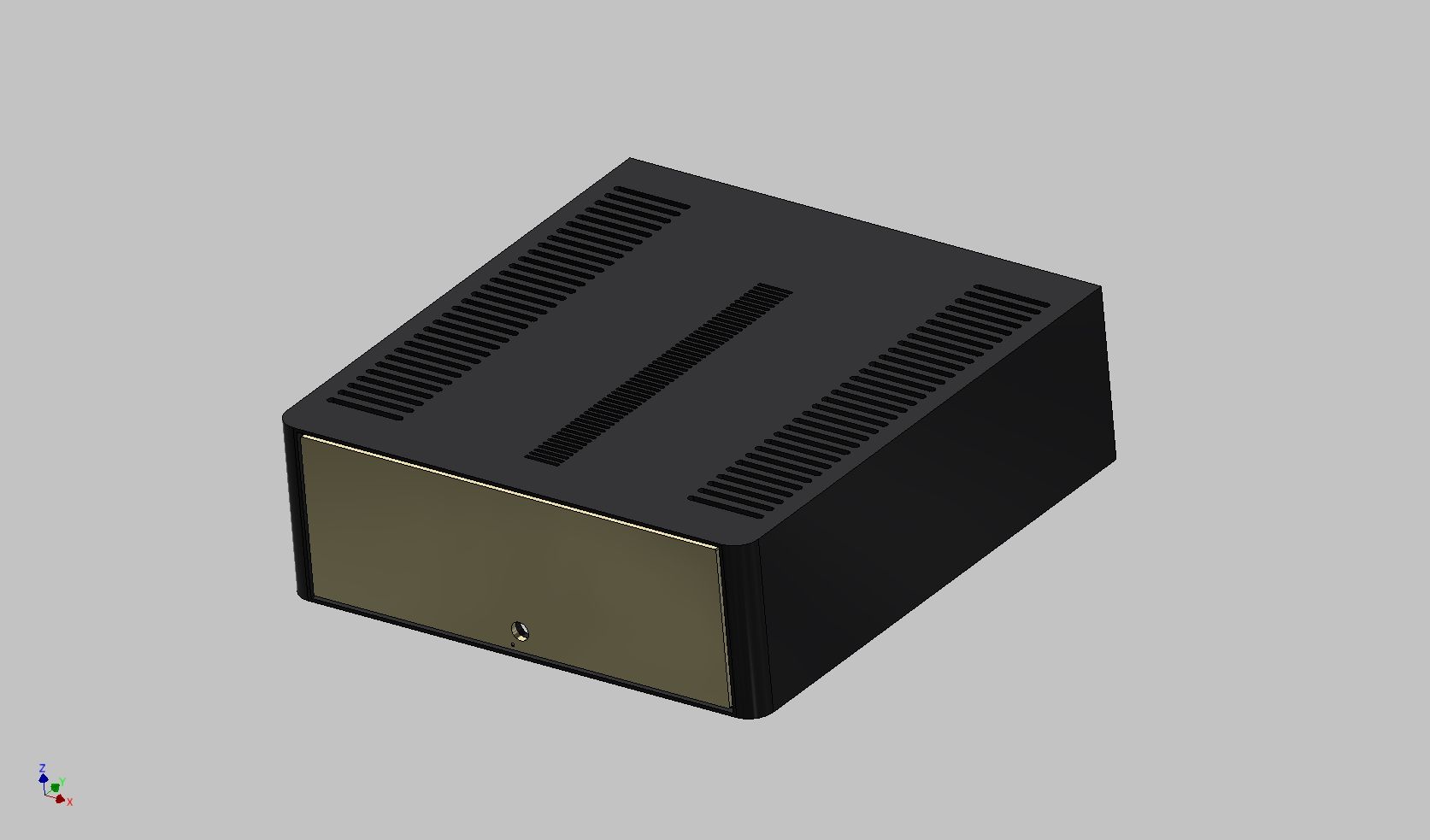

From the 3D drawing to the final enclosure (part 1 – milling)

The 3D drawing in Autocad Inventor Front view with the gold plated stainless steel front

The 3D drawing in Autocad Inventor upside down with “virtual mounted” heat sinks

We start with an 80kg aluminum block.

It takes hours to mill the desired structure

Only the gaps for the heatsinks are missing

The first of 4 enclosures is perfected. The next step will be the surface treatment and afterwards the varnishing.